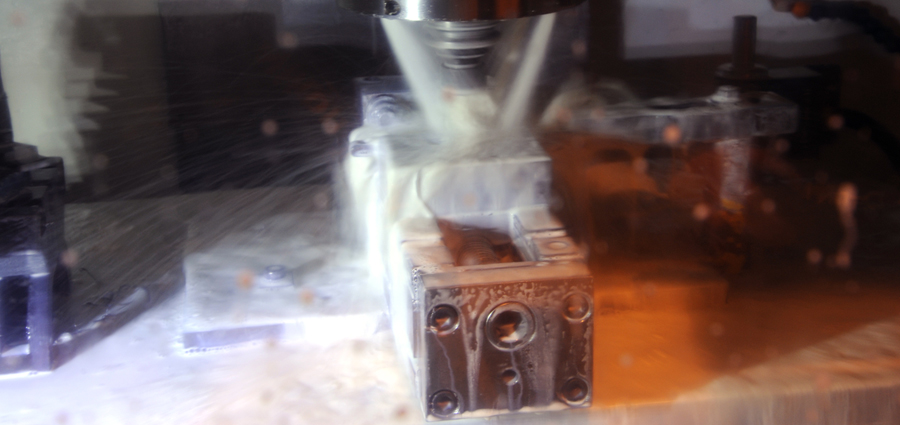

CNC Milling

Component Supplies has a wide variety of machining centres, suitable for most customers needs. We always invest in high quality machinery to maximise reliability and performance which reduces cycle times and as a result component cost.

Our machines have a wide range of cutting envelopes to accommodate both large and small components, for more detail on these see our capacity list where sizes are stated.

We produce our own fixtures so can hold complex cast parts for ancillary machining operations, we also have a wide range of vices and other clamping mechanisms for clamping billets to machine components from solid.

We welcome enquiries based on free issue castings or systems requiring the purchase of raw materials.

-

Five Axis Milling

Component Supplies has both 3+2 and full 5 axis machining capability, depending on customers needs this can: reduce the number of operations required to manufacture a component, increase accuracy and reducing finished component lead time or can facilitate the machining of complex features otherwise not possible with standard machinery.

As always Component Supplies has invested in premium quality machinery and work holding devices to reinforce our capability in this area.

Our 5 axis machining centres also feature in-cycle probing, to further increase their versatility and accuracy. Amongst other things the probing facility allows us to align machined features to cast faces (or other less accurate features) in process, ensuring errors such as ‘thick thin’ remaining material to cast faces can be avoided.

Our in cycle probing also allows us to check critical size features in process to ensure every component conforms to exacting tolerances.